Category Archive: Uncategorized

An Important Factor in Bearing Maintenance

While bearings remain some of the most rugged and resilient components, they can still fall prey to the problems of

While bearings remain some of the most rugged and resilient components, they can still fall prey to the problems of

wear.

Unremedied, worn bearings can result in much larger problems; their failure almost inevitably brings mechanical systems to a halt until they can be repaired. To avoid this expensive downtime, it is essential to learn the various sources of wear in rolling element bearings.

One of these factors is the operating speed of the bearings’ mechanical system. High speed applications play a common role in roller bearings applications; ensuring proper maintenance will help protect against the excessive wear that can lead to system failure.

The Perils of High Speeds

Excessive speed can have a number of impacts on the life of bearings, two of the most important being heat and friction. High speed operation can accelerate wear for bearing systems that are either not designed to handle it or improperly lubricated. The following are a few of the detrimental impacts that can occur under these conditions:

Churning

With high speed operations, bearings can reach very high temperatures by churning in oil or grease. Lubricant is required to mitigate the natural friction that occurs between two bearings operating at high speeds; however, higher levels of bearing action can result in decreased viscosity in lubricants. This loss of viscosity is defined as churning, and continued bearing action during churning causes agitation that can ultimately cause the lubricant to fail and the bearings to overheat.

Breakage

When working at higher speeds, bearings naturally gather greater inertial forces. If lubrication is not adequate, or bearings exhibit sudden stopping and starting, the forces between the retainer and the rolling bearings can become even greater. If not dealt with, these inertial forces can ultimately cause retainers and bearing cages to break, causing overall system breakdowns.

Slippage

Another difficulty that can arise from a lack of lubricant and higher speeds is slippage between the raceways and rolling elements. This most often occurs when the lubricant coating is absent from bearing contact areas. When this contact is made at high speeds and without lubricant, wear can occur at a rapid rate. Tightly loaded bearings have the greatest risk of slippage under these circumstances.

Remedies to Extend Service Life

While the above demonstrates the various difficulties that can arise from high speed operations, the solutions are fairly simple. You can maximize bearing longevity by ensuring proper lubrication and making load adjustments when required.

Lubrication: The Key to Maximum Bearing Service Life

The proper care of bearings will ensure their place as one of the most reliable components in nearly any system. The issues of churning, breakage, and slippage can all be addressed with proper lubrication.

The proper care of bearings will ensure their place as one of the most reliable components in nearly any system. The issues of churning, breakage, and slippage can all be addressed with proper lubrication.

It is essential to get the correct balance when lubricating bearing systems. Too much lubricant runs the risk of churning, while too little does not adequately separate bearing parts. Proper lubrication will reduce bearing wear in the highest speed settings, protecting against costly and potentially dangerous breakdowns.

It is also important to keep in mind that lubrication has a limited service life as well. When subject to mechanical stress and aging, lubrication loses a certain amount of viscosity and lubricity, leading to conditions like churning. Relubrication can be beneficial when this is the case, keeping wear to a minimum during the most difficult industrial conditions.

Adjusting Load and Bearing Sizes

When systems have adequate lubrication, wear from high speed operation can still occur if the bearings have not been properly matched with the load requirements of the application. This can be solved by either changing the system’s overall load, which is not always an option, or employing proper bearings.

For example, in the case of slippage, damage can occur when the load on the bearings is too light. An increased load under these circumstances will lessen the chance of a slip occurring. In lieu of a load increase, this problem can also be lessened by installing smaller bearings. These adjustments are enormously helpful in solving the issues that occur from high-speed applications.

Action Bearing: High Quality Bearings of All Varieties

Action Bearing has more than 50 years of experience in bringing customers the most appropriate roller and ball bearings to fulfill their exact specifications. Quality products from Action provide the industry’s best reliability and longevity — with proper maintenance, they can outlast the equipment in which they are installed.

To learn more about how to prevent failure due to high speeds and other issues, download our Bearing Failure Analysis Guide today.

A Major Influence on Service Life

When examining the factors that can affect the service life of bearings, it is important to remember environmental considerations. Bearing failure is rarely caused by bearing material or manufacturing problems; instead, it is frequently due to the effect of foreign substances on bearing functionality. The amount of dirt, debris, or other contaminants that bearings encounter plays a direct role in how long they remain functional and effective. Ignoring such wear can lead to breakage or even system failure if the environmental contaminations remain unaddressed.

The Effects of Environmental Influence

A variety of environmental factors can detrimentally affect bearing service life, including:

Dirt and Dust

Foreign particles, such as dirt and dust, can be some of the most significant sources of wear in bearings. After engraining themselves within the bearings, contaminants can cause significant damage and potentially lead to system failure.

These foreign particles can also contaminate lubricant used in a bearing, causing accelerated wear and significant damage. Severity of bearing damage and its subsequent effect on bearing service life depends on the size, hardness, and concentration of contaminants, in addition to the amount and viscosity of lubricant used on the bearing. More viscous lubrication reduces the level of wear for the contaminated bearing.

Water

The same damage done by dirt and dust can also occur with water or other aggressive media, including metallic debris. When suspended or dissolved water in lubricant interacts with a bearing, it can cause etching and microcracks that reduce the integrity of the bearing.

External Heat

A system operating at high temperatures can cause bearing fatigue and damage from overheating. When selecting the proper bearing and lubrication for your application, it is important to consider the required operating temperature and running schedule (intermittent vs. continuous) that the bearing will need to support.

Electrolytic Corrosion

In some applications, bearings come into close proximity to currents, which cause sparks that can pit or flute on the surface of the bearing. To correct this, install a bypass circuit or outfit bearings with insulation to prevent sparking effects.

Remedies for Environmental Contamination

Like many other potential bearing difficulties, the best defense against environmental wear and failure is the use of high-quality products proven to be effective for their specific application. This includes:

• Sealing — Proper sealing is essential for eliminating dust, dirt, and water from bearings. A number of different specialty seals are available to keep water, metallic debris, and other contaminants out without affecting the functionality of your bearings.

• Lubrication — It is vital that lubrication does not become contaminated, as this causes wear acceleration. Maintaining both the proper amount and type of lubricant will ensure dependable bearing longevity.

• Insulation — For applications in which a bearing comes into contact with current sparks, it is important to use insulating materials to prevent bearing degradation or failure. Applied either directly on or within the bearing, such insulation should be a required design consideration for bearing applications like power-generation equipment.

At Action Bearing, we lead the industry in providing the best bearings for even the most grueling applications. We are proud to offer our Action Bearing Failure Analysis guide, providing comprehensive information to help you to correct and prevent future bearing failures — even in the most difficult environmental conditions. To learn more about our products or request a quote, contact us today.

Rolling bearings are precision bearings, such as balls or rollers, which carry loads in a variety of applications with relatively little resistance. They are durable in even the toughest conditions and maintain a long service life; this can be projected as a period of time or a total number of rotations depending on the application.

Over 99% of rolling bearings reach their expected service life. In fact, most causes of premature failure, such as rust, corrosion, pitting, and skewing, are preventable. To protect rolling bearings from long-term damage and premature failure, you can cover the sliding contact surfaces with a thin film of lubrication that separates the rollers and raceways.

Over 99% of rolling bearings reach their expected service life. In fact, most causes of premature failure, such as rust, corrosion, pitting, and skewing, are preventable. To protect rolling bearings from long-term damage and premature failure, you can cover the sliding contact surfaces with a thin film of lubrication that separates the rollers and raceways.

Engineers typically use grease to lubricate bearings because it is easy to handle and offers protective sealing capabilities for the system. Another lubrication option is oil, which flows freely and carries away heat, making it suitable for high speed or high temperature operations.

When applied properly, rolling bearing lubrication can:

• Reduce the friction and abrasions caused by direct metal-to-metal contact

• Transport heat generated by friction

• Prolong overall bearing service life

• Prevent harmful rust and corrosion

• Prevent foreign objects and contamination from interfering with the rolling elements

Just as normal rolling bearings have an expected service life, grease does as well. Engineers must consider this factor and diligently reapply lubrication to sustain proper bearing function. When done effectively, lubrication enhances bearing reliability and increases overall service life.

Lubrication is a crucial part of rolling bearing success, but it’s important to be mindful of some potential pitfalls:

• Selecting the wrong lubricant type – Grease and oil each have their own advantages and disadvantages, depending on the specific application.

• Using too much or too little grease/oil – Too much grease can cause bearing temperature to rise, especially when operating at high speeds, while too little grease results in harmful metal-to-metal contact.

• Mixing grease and oil – Each type of lubricant provides different benefits, but they should always be used separately.

• Contaminating the grease/oil with objects or water – The lubricant’s primary function should be to seal the contact surface and prevent the entrance of media or water.

Action Bearing has had “Bearings on the Brain” for over 50 years. Whether you’re looking for a hard-to-find bearing or need help selecting the right type of lubricant for your system, our team of specialists will examine your application and make an expert recommendation.

For more information about the vital elements of rolling bearings, we invite you to download our eBook The Art of Precision Bearings or visit our website.

Precision bearings are industrial components that carry loads in a variety of applications. Roller bearings, which operate with rolling elements such as balls or rollers in a raceway, are reliable and durable. In fact, more than 99% of rolling bearings reach their projected service life, even in the toughest conditions.

While only a small percentage of such bearings fail, this premature failure can be caused by a number of factors. Flaking, pitting, spalling, rusting, corroding, creeping, and skewing can all lead to failure; each concern stems from a small group of interrelated and preventable causes. Some of the most common ones include:

While only a small percentage of such bearings fail, this premature failure can be caused by a number of factors. Flaking, pitting, spalling, rusting, corroding, creeping, and skewing can all lead to failure; each concern stems from a small group of interrelated and preventable causes. Some of the most common ones include:

Improper lubrication – Lubrication enhances function and prolongs bearing service life, but only if done correctly. Too much or too little grease, mixed lubricants, and contamination can all have adverse effects on the bearings. Lubricated bearings also have a “grease service life,” which is a state of optimal function between lubrications. If an engineer neglects to reapply lubrication when this time expires, the bearing can fail.

Mounting and installation of bearings – It is crucial to use proper tools and heaters during the mounting process. If mounting pressure is applied to the wrong ring during installation, particularly with self-aligning bearings, the raceways and rolling elements can become dented. If the fit is too loose, tight, or misaligned, the preload weight will be skewed and could cause the shaft to rotate or creep.

Operational stress and bearing selection – Although roller bearings are generally reliable, the overall application they work within may change over time. If the load within an application becomes too high or too low, bearings could fatigue or skid, respectively. Warning signs of these failures include rising temperatures and unusual noises.

Environmental influences – Dust, dirt, media, water, and unwanted heat can all contaminate your bearings if they’re not properly sealed. Depending on the application, a bearing may require insulation to prevent electrical currents and sparks. Be mindful of outside factors that could interfere with your specific application and be aware of precautions you could take to prevent such problems.

Considering different bearing technologies and identifying the one most suitable to your specific application is the first step in the prevention of bearing failure. By keeping these causes and their warning signs in mind, you can proactively make corrections to avoid premature failures and additional costs.

Action Bearing has over 50 years of ball and roller bearing expertise. We serve original equipment manufacturer (OEMs) and maintenance markets around the world to help customers find the right bearing at the right price. To learn more about the causes and cures of premature bearing failure, we invite you to read our eBook, “Bearing Failure Analysis.”

Bearings—just like people—have to deal with stress. It’s important when choosing a bearing to make sure that it doesn’t get “stressed out”. In other words, it’s important to make sure that the carrying capacity of the bearing can handle the amount of load it will experience.

If a load is too big for the bearing’s carrying capacity then accelerated fatigue or even plastic deformation can occur, resulting in a shortened service life. There are two kinds of stresses to consider when choosing a bearing: static and dynamic.

Static stress doesn’t necessarily mean that the load itself is static. “Static” actually refers to the state of the bearing, not the load. Static stressing occurs when a load, either constant or variable, is applied to a bearing that is stationary or moving very slowly. If the load is too big it can cause plastic deformation of the rolling surfaces and even flatten the rolling elements, which can prematurely and catastrophically end the life of the bearing.

Static stress doesn’t necessarily mean that the load itself is static. “Static” actually refers to the state of the bearing, not the load. Static stressing occurs when a load, either constant or variable, is applied to a bearing that is stationary or moving very slowly. If the load is too big it can cause plastic deformation of the rolling surfaces and even flatten the rolling elements, which can prematurely and catastrophically end the life of the bearing.

Dynamic stress also refers to the motion of the bearing, not the load. Dynamic stress occurs when a load, constant or variable, is applied to a rotating bearing. If the load is too big for the carrying capacity of the bearing, it will cause fatigue in the bearing prematurely and cause cracks and flakes in weak points. This will result in failure due to material fatigue, i.e. the death of your bearing.

There are three theories as to what kinds stresses cause failure due to fatigue. The theory of maximum shear stress hypothesizes that the main culprit is the maximum shear stress on the bearing. Distortion theory assumes that stresses in a zone, rather than at a single point, cause fatigue. The final theory of alternating shear stresses claims that the orthogonal stresses on the bearing are the cause of material fatigue.

Although there is some supporting evidence for each of these theories, the alternating shear stress theory is what is commonly used for calculating the fatigue life of rolling bearings. The fatigue life, or rating life, is defined as the number of revolutions or number of hours, at a constant speed, reached or exceeded by 90% of a group of dimensionally identical bearings before the first signs of material fatigue appear. Typically the rating life of a group of bearings decreases as the load increases.

The expert technical team at Action Bearing is available to help make sure that your bearings don’t get “stressed out”. We can help you with all your bearing needs. Contact us today or visit our Catalog and Technical Toolbox webpages for more information on how we can serve you.

While there might be a few youngsters out there who still believe every gift they receive was made in Santa’s workshop, high-quality, long-lasting toys are made possible by committed manufacturers working with the best components.

High-tech gadgets may rate highly on many people’s lists, but a multitude of sought-after toys and games still employ basic mechanical devices such as bearings. These gifts require bearings to run smoothly and safely, as well as to help provide maximum levels of enjoyment throughout their lifetimes.

Toys such as radio-controlled cars, yo-yos, skateboards, tops, scooters, roller skates, and jump ropes all rely on bearings for their overall functionality. The same types of bearings that are so important for industrial applications also play a vital role in the design and structure of toys. Whether steel, ceramic, 7mm, 8mm, or 608 bearings, many gifts would never function at all without bearings.

Applications that Keep the Fun Rolling (or Spinning)

Sealed ball bearings of all different sizes are vital for remote-controlled cars. They allow operators to steer cars freely and for engines to work at high speeds.

Another toy that utilizes bearings for high performance is the yo-yo; ball bearings reduce friction while a yo-yo spins at the end of the string. Enthusiasts have used yo-yos with steel bearings for decades, but for even better performance and corrosion prevention, some yo-yos are made with ceramic, instead of steel, bearings.

There are other toys that use ball bearings, as well; ones that you wouldn’t necessarily expect to need them. For instance, many spinning tops utilize independent ball bearings to help them spin on any surface. Even top-of-the-line jump ropes have ball bearings — they often use precision and swivel ball bearings that eliminate friction and maximize the rotation speed of the rope.

Travel in Style

Why settle for walking when you can skate? Any toy with wheels will need bearings for functional, safe, and efficient operation.

Skateboards rely on 608 standard bearings to eliminate friction between the metal in each wheel and the axle it spins around. The scooter, a popular toy, is evolving into a serious mode of transportation. Both sealed and shielded bearings are used to provide maximum protection during outdoor use. Roller skating, one of the oldest recreational pastimes, would be impossible without bearings — two bearings are used per wheel to allow it to move freely.

Action Bearing Provides for Every Bearing Need

Whether used for toys and gifts or major industrial applications, bearings play an important role in applications across the board. No matter what your next bearing project, the experts at Action Bearing will be able to help you find the exact product to suit your unique requirements.

We offer a full array of informational tools and some of the most experienced personnel in the industry, ready to assist you. To find out more or to receive a quote, contact us today.

The first time you choose a bearing catalog, it can be intimidating and confusing. The catalog can seem to be written in a secret code, with a series of letters and numbers that are unknown to anyone who hasn’t chosen a bearing before. This blog post will help you crack the code and understand how to get the most from your bearings.

Rolling bearings are designated by codes that indicate the construction, dimensions, tolerances, and clearances of each bearing. Tolerance is the limit of random (unintentional) deviation of a dimension from its nominal value. Allowance is the amount of designed (intentional) deviation between two mating dimensions in a fit, which, in combination with their respective tolerances, results into a maximum and minimum clearance or interference.

Rolling bearings are designated by codes that indicate the construction, dimensions, tolerances, and clearances of each bearing. Tolerance is the limit of random (unintentional) deviation of a dimension from its nominal value. Allowance is the amount of designed (intentional) deviation between two mating dimensions in a fit, which, in combination with their respective tolerances, results into a maximum and minimum clearance or interference.

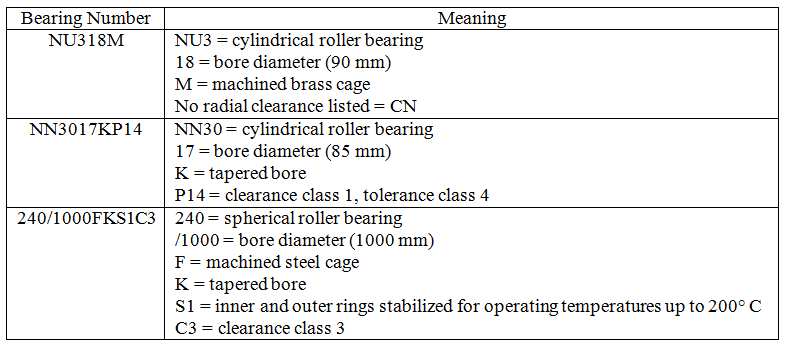

The codes in a bearing catalog can include any or all of these three parts: the basic code, prefixes, and suffixes. The basic code tells you what kind of bearing it is and its bore diameter (diameter of the inner ring). Prefixes indicate basic components in the bearing, and suffixes indicate any special characteristics or designs.

Basic Code

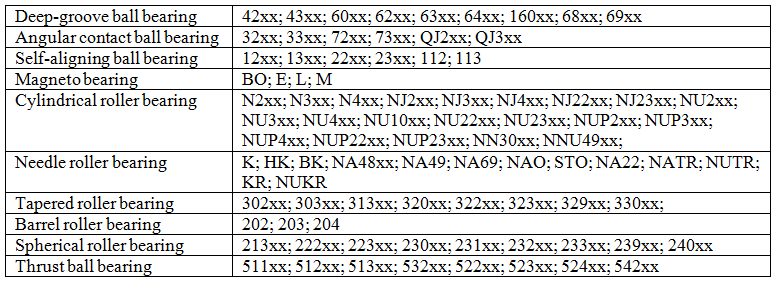

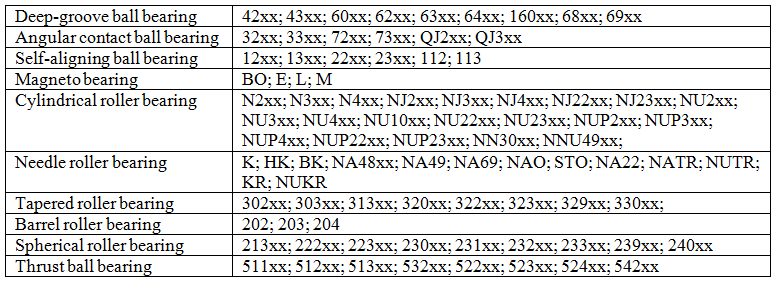

The basic code consists of the bearing series, which indicates the type of bearing, and the bore number, which specifies the bore diameter. The bearing series can be made up of letters and/or numbers that designate the construction, diameter series, and in many cases the width series. Table 1 shows the bearing series for the most common bearing types.

Table 1. Bearing series for common bearing types

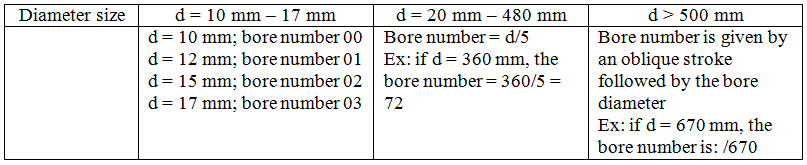

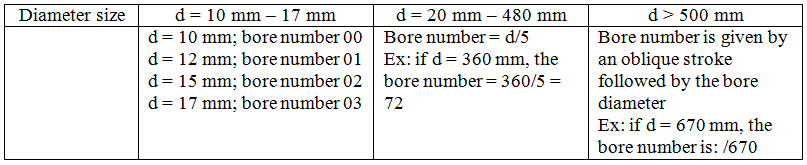

The bore number indicates the bore diameter. See Table 2.

Table 2. Bore numbers for bore diameters.

If the bearing code only contains the basic code and doesn’t include any prefixes or suffixes, it means that it is a normal bearing with normal standards of form, precision, and clearance.

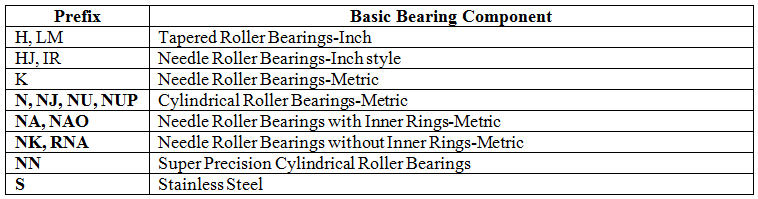

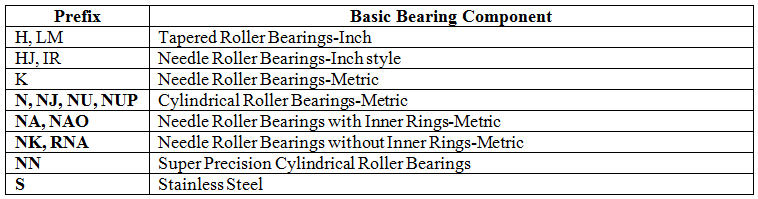

Prefixes

Prefixes refer to basic bearing components. Common prefixes are shown in Table 3.

Table 3. Common Prefixes.

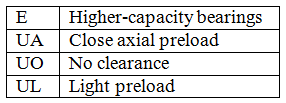

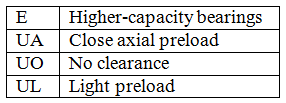

Suffixes

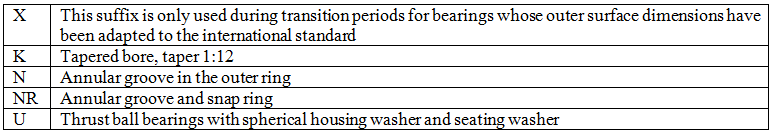

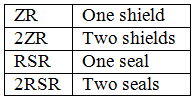

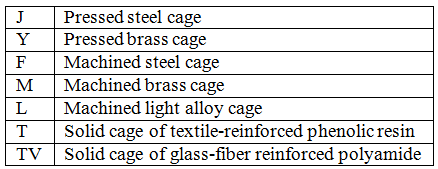

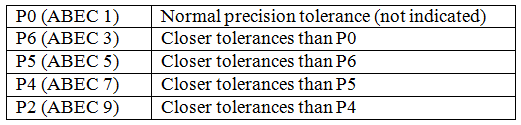

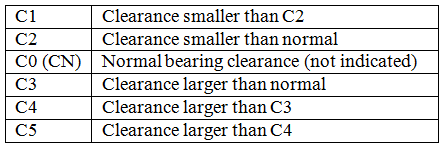

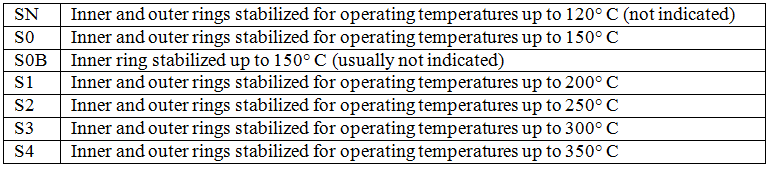

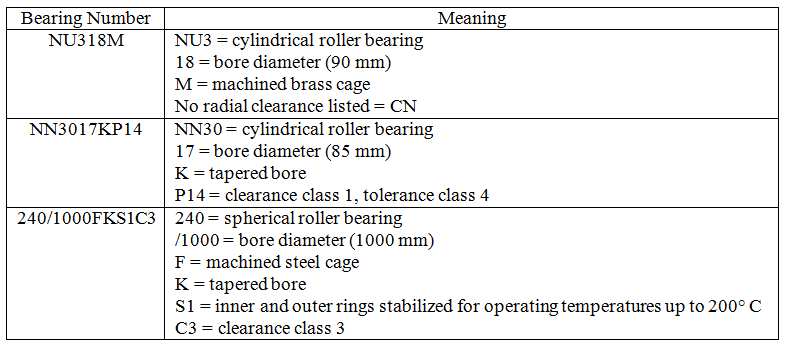

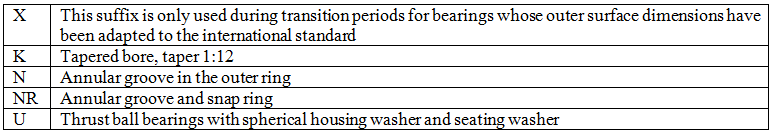

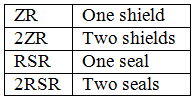

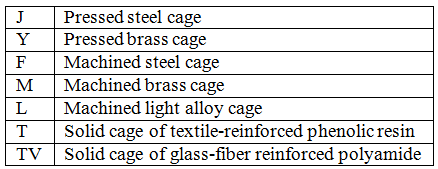

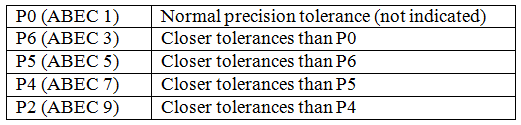

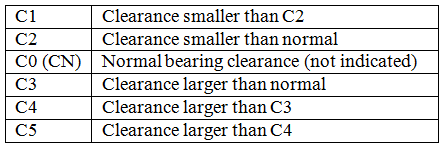

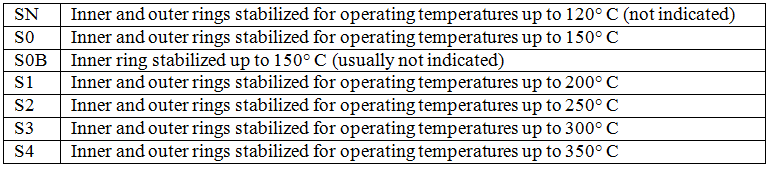

Suffixes indicate bearings with special characteristics or designs, including special outer forms, cages, precision tolerances, clearances, and other characteristics like heat treatment and noise behavior. The most common suffixes are described in the tables below.

Table 4. Suffizes for internal design

Table 5. Suffixes for outer surface dimensions

Table 6. Suffixes for Sealings

Table 7. Suffixes for cage materials

Table 8. Suffixes for precision tolerances

Table 9. Suffixes for bearing clearances

For bearings with both special precision tolerance and special clearance, the suffixes are combined. For example, the suffix for a bearing with tolerance P6 and clearance C3 is P63.

Table 10. Suffixes for dimensionally stabilized bearings

Examples

Table 11. Example of Bearings Numbers and Codes

At Action Bearing we are here to help you find the bearing you need. We have years of experience and we are available to help you with all your bearing needs. For more information visit our Catalog and Technical Toolbox webpages, or contact us today.

Have you ever looked at a bearing catalogue and felt like you were reading a foreign language, with bearing tolerances written in a series of letters that you’re sure are supposed to make sense? At Emerson Bearing, we want to help you choose the right bearing for your application. That is why we’ve prepared this blog post to help you decipher the language of bearing tolerances.

(more…)

At Action Bearing, we understand how crucial it is to choose the right bearing for the right application. If you need to extend the service life of your bearing, you must first consider the kinds of things that can cause wear so that they can be avoided or resolved.

At Action Bearing we know that the service life of your bearing is important and want to help make sure that your bearing doesn’t get worn out too soon. This blog post aims to describe bearing wear and service life to help you get the most out of your bearings.

What is wear?

In a rolling bearing, wear is material abrasion occurring at contact surfaces. The amount of wear that develops depends on the environmental and operating conditions to which the bearing is exposed.

The main causes of wear include: dirt and foreign particles entering the bearing, insufficient lubrication, lubricant deterioration, corrosion caused by water condensation inside the bearing, exposure to corrosive liquids and fumes, and chemically aggressive EP (extreme pressure) lubricant additives.

Why do we worry about wear?

Wear has a detrimental effect on operation and service life, it can increases noise and bearing clearance, which can make a machine run less accurately. If left unchecked, abrasion can create a snowball effect and wear down the contact surfaces of the bearing until it is no longer usable. Early warning signs for wear include scratched raceways, running noise, and running tracks with a dull appearance.

How can you minimize wear on your bearings?

The best way to minimize wear is to make sure that your bearing has good internal lubrication and that the bearing stays as clean as possible. Avoiding exposure to dirt and corrosive materials can significantly minimize the amount of wear that develops.

If your bearing is well lubricated, well-sealed, kept clean, and not overloaded it can run wear free for a long time. However, there are some applications in which it’s really difficult to keep a bearing clean, or where it is difficult to avoid corrosive agents. In these cases it may cost more to keep the bearing clean and wear free then it is to just replace a worn out bearing.

A bearing should be replaced before it fails completely so that operation is not unduly interrupted. The service life of a bearing depends on how quickly wear develops and the severity of the wear. Fatigue life for cases of severe wear should be calculated using Eschmann’s estimation procedure.

To learn more about the causes of bearing wear and how to avoid them, please visit our Bearing Failure Analysis page. It contains valuable information on the different causes of bearing failure and the corrective actions that can be taken to avoid them. Contact us today or visit our Catalog to learn more about how we can help you.

Please visit Emersonbearing.com for our latest blogs and updates!

Please visit Emersonbearing.com for our latest blogs and updates! While bearings remain some of the most rugged and resilient components, they can still fall prey to the problems of

While bearings remain some of the most rugged and resilient components, they can still fall prey to the problems of The proper care of bearings will ensure their place as one of the most reliable components in nearly any system. The issues of churning, breakage, and slippage can all be addressed with proper lubrication.

The proper care of bearings will ensure their place as one of the most reliable components in nearly any system. The issues of churning, breakage, and slippage can all be addressed with proper lubrication.

While only a small percentage of such bearings fail, this premature failure can be caused by a number of factors. Flaking, pitting, spalling, rusting, corroding, creeping, and skewing can all lead to failure; each concern stems from a small group of interrelated and preventable causes. Some of the most common ones include:

While only a small percentage of such bearings fail, this premature failure can be caused by a number of factors. Flaking, pitting, spalling, rusting, corroding, creeping, and skewing can all lead to failure; each concern stems from a small group of interrelated and preventable causes. Some of the most common ones include: Static stress doesn’t necessarily mean that the load itself is static. “Static” actually refers to the state of the bearing, not the load. Static stressing occurs when a load, either constant or variable, is applied to a bearing that is stationary or moving very slowly. If the load is too big it can cause plastic deformation of the rolling surfaces and even flatten the rolling elements, which can prematurely and catastrophically end the life of the bearing.

Static stress doesn’t necessarily mean that the load itself is static. “Static” actually refers to the state of the bearing, not the load. Static stressing occurs when a load, either constant or variable, is applied to a bearing that is stationary or moving very slowly. If the load is too big it can cause plastic deformation of the rolling surfaces and even flatten the rolling elements, which can prematurely and catastrophically end the life of the bearing.

Rolling bearings are designated by codes that indicate the construction, dimensions, tolerances, and clearances of each bearing. Tolerance is the limit of random (unintentional) deviation of a dimension from its nominal value. Allowance is the amount of designed (intentional) deviation between two mating dimensions in a fit, which, in combination with their respective tolerances, results into a maximum and minimum clearance or interference.

Rolling bearings are designated by codes that indicate the construction, dimensions, tolerances, and clearances of each bearing. Tolerance is the limit of random (unintentional) deviation of a dimension from its nominal value. Allowance is the amount of designed (intentional) deviation between two mating dimensions in a fit, which, in combination with their respective tolerances, results into a maximum and minimum clearance or interference.