Levels of Precision – Don’t Stress: How Load-Carrying Capacity Affects Bearing Service Life

Leave a CommentBearings—just like people—have to deal with stress. It’s important when choosing a bearing to make sure that it doesn’t get “stressed out”. In other words, it’s important to make sure that the carrying capacity of the bearing can handle the amount of load it will experience.

If a load is too big for the bearing’s carrying capacity then accelerated fatigue or even plastic deformation can occur, resulting in a shortened service life. There are two kinds of stresses to consider when choosing a bearing: static and dynamic.

Static stress doesn’t necessarily mean that the load itself is static. “Static” actually refers to the state of the bearing, not the load. Static stressing occurs when a load, either constant or variable, is applied to a bearing that is stationary or moving very slowly. If the load is too big it can cause plastic deformation of the rolling surfaces and even flatten the rolling elements, which can prematurely and catastrophically end the life of the bearing.

Static stress doesn’t necessarily mean that the load itself is static. “Static” actually refers to the state of the bearing, not the load. Static stressing occurs when a load, either constant or variable, is applied to a bearing that is stationary or moving very slowly. If the load is too big it can cause plastic deformation of the rolling surfaces and even flatten the rolling elements, which can prematurely and catastrophically end the life of the bearing.

Dynamic stress also refers to the motion of the bearing, not the load. Dynamic stress occurs when a load, constant or variable, is applied to a rotating bearing. If the load is too big for the carrying capacity of the bearing, it will cause fatigue in the bearing prematurely and cause cracks and flakes in weak points. This will result in failure due to material fatigue, i.e. the death of your bearing.

There are three theories as to what kinds stresses cause failure due to fatigue. The theory of maximum shear stress hypothesizes that the main culprit is the maximum shear stress on the bearing. Distortion theory assumes that stresses in a zone, rather than at a single point, cause fatigue. The final theory of alternating shear stresses claims that the orthogonal stresses on the bearing are the cause of material fatigue.

Although there is some supporting evidence for each of these theories, the alternating shear stress theory is what is commonly used for calculating the fatigue life of rolling bearings. The fatigue life, or rating life, is defined as the number of revolutions or number of hours, at a constant speed, reached or exceeded by 90% of a group of dimensionally identical bearings before the first signs of material fatigue appear. Typically the rating life of a group of bearings decreases as the load increases.

The expert technical team at Action Bearing is available to help make sure that your bearings don’t get “stressed out”. We can help you with all your bearing needs. Contact us today or visit our Catalog and Technical Toolbox webpages for more information on how we can serve you.

Bearing the Holidays Made Easy: How Bearings Are Used in Toys for All Ages

Leave a CommentWhile there might be a few youngsters out there who still believe every gift they receive was made in Santa’s workshop, high-quality, long-lasting toys are made possible by committed manufacturers working with the best components.

High-tech gadgets may rate highly on many people’s lists, but a multitude of sought-after toys and games still employ basic mechanical devices such as bearings. These gifts require bearings to run smoothly and safely, as well as to help provide maximum levels of enjoyment throughout their lifetimes.

Toys such as radio-controlled cars, yo-yos, skateboards, tops, scooters, roller skates, and jump ropes all rely on bearings for their overall functionality. The same types of bearings that are so important for industrial applications also play a vital role in the design and structure of toys. Whether steel, ceramic, 7mm, 8mm, or 608 bearings, many gifts would never function at all without bearings.

Applications that Keep the Fun Rolling (or Spinning)

Sealed ball bearings of all different sizes are vital for remote-controlled cars. They allow operators to steer cars freely and for engines to work at high speeds.

Another toy that utilizes bearings for high performance is the yo-yo; ball bearings reduce friction while a yo-yo spins at the end of the string. Enthusiasts have used yo-yos with steel bearings for decades, but for even better performance and corrosion prevention, some yo-yos are made with ceramic, instead of steel, bearings.

There are other toys that use ball bearings, as well; ones that you wouldn’t necessarily expect to need them. For instance, many spinning tops utilize independent ball bearings to help them spin on any surface. Even top-of-the-line jump ropes have ball bearings — they often use precision and swivel ball bearings that eliminate friction and maximize the rotation speed of the rope.

Travel in Style

Why settle for walking when you can skate? Any toy with wheels will need bearings for functional, safe, and efficient operation.

Skateboards rely on 608 standard bearings to eliminate friction between the metal in each wheel and the axle it spins around. The scooter, a popular toy, is evolving into a serious mode of transportation. Both sealed and shielded bearings are used to provide maximum protection during outdoor use. Roller skating, one of the oldest recreational pastimes, would be impossible without bearings — two bearings are used per wheel to allow it to move freely.

Action Bearing Provides for Every Bearing Need

Whether used for toys and gifts or major industrial applications, bearings play an important role in applications across the board. No matter what your next bearing project, the experts at Action Bearing will be able to help you find the exact product to suit your unique requirements.

We offer a full array of informational tools and some of the most experienced personnel in the industry, ready to assist you. To find out more or to receive a quote, contact us today.

Levels of Precision – How Bearing Numbers and Codes Affect Bearing Life

Leave a CommentThe first time you choose a bearing catalog, it can be intimidating and confusing. The catalog can seem to be written in a secret code, with a series of letters and numbers that are unknown to anyone who hasn’t chosen a bearing before. This blog post will help you crack the code and understand how to get the most from your bearings.

Rolling bearings are designated by codes that indicate the construction, dimensions, tolerances, and clearances of each bearing. Tolerance is the limit of random (unintentional) deviation of a dimension from its nominal value. Allowance is the amount of designed (intentional) deviation between two mating dimensions in a fit, which, in combination with their respective tolerances, results into a maximum and minimum clearance or interference.

Rolling bearings are designated by codes that indicate the construction, dimensions, tolerances, and clearances of each bearing. Tolerance is the limit of random (unintentional) deviation of a dimension from its nominal value. Allowance is the amount of designed (intentional) deviation between two mating dimensions in a fit, which, in combination with their respective tolerances, results into a maximum and minimum clearance or interference.

The codes in a bearing catalog can include any or all of these three parts: the basic code, prefixes, and suffixes. The basic code tells you what kind of bearing it is and its bore diameter (diameter of the inner ring). Prefixes indicate basic components in the bearing, and suffixes indicate any special characteristics or designs.

Basic Code

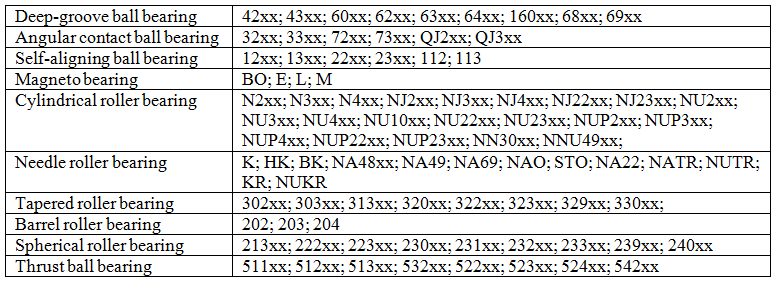

The basic code consists of the bearing series, which indicates the type of bearing, and the bore number, which specifies the bore diameter. The bearing series can be made up of letters and/or numbers that designate the construction, diameter series, and in many cases the width series. Table 1 shows the bearing series for the most common bearing types.

Table 1. Bearing series for common bearing types

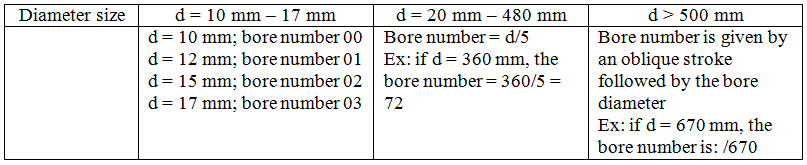

The bore number indicates the bore diameter. See Table 2.

Table 2. Bore numbers for bore diameters.

If the bearing code only contains the basic code and doesn’t include any prefixes or suffixes, it means that it is a normal bearing with normal standards of form, precision, and clearance.

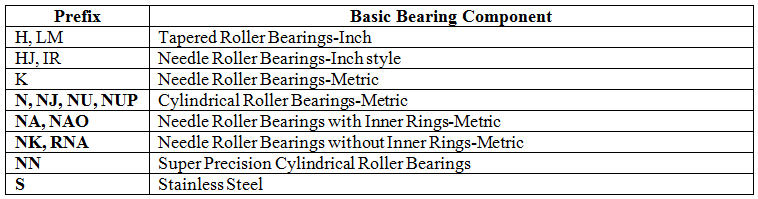

Prefixes

Prefixes refer to basic bearing components. Common prefixes are shown in Table 3.

Table 3. Common Prefixes.

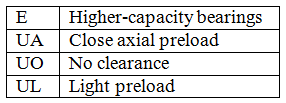

Suffixes

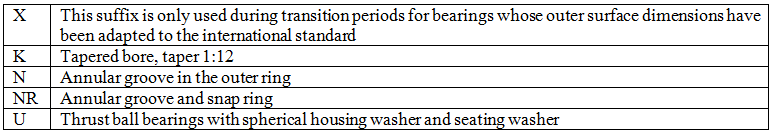

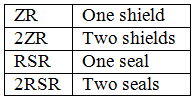

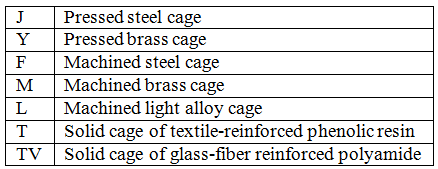

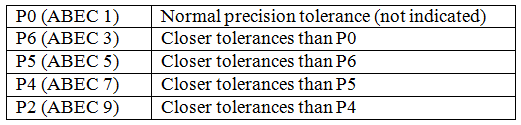

Suffixes indicate bearings with special characteristics or designs, including special outer forms, cages, precision tolerances, clearances, and other characteristics like heat treatment and noise behavior. The most common suffixes are described in the tables below.

Table 4. Suffizes for internal design

Table 5. Suffixes for outer surface dimensions

Table 6. Suffixes for Sealings

Table 7. Suffixes for cage materials

Table 8. Suffixes for precision tolerances

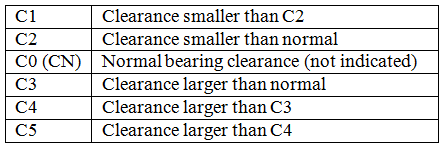

Table 9. Suffixes for bearing clearances

For bearings with both special precision tolerance and special clearance, the suffixes are combined. For example, the suffix for a bearing with tolerance P6 and clearance C3 is P63.

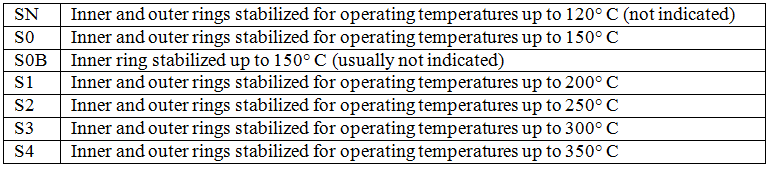

Table 10. Suffixes for dimensionally stabilized bearings

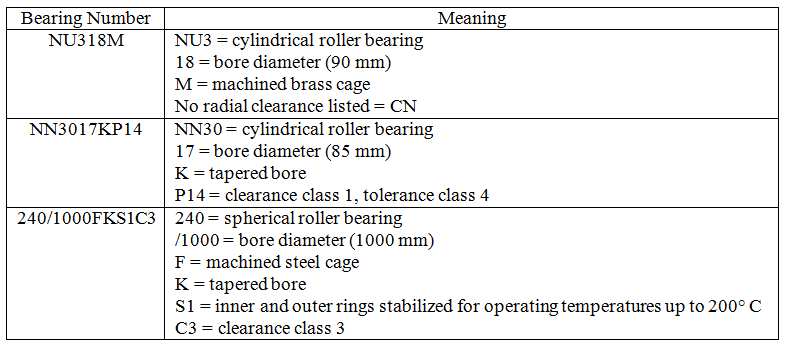

Examples

Table 11. Example of Bearings Numbers and Codes

At Action Bearing we are here to help you find the bearing you need. We have years of experience and we are available to help you with all your bearing needs. For more information visit our Catalog and Technical Toolbox webpages, or contact us today.

Please visit Emersonbearing.com for our latest blogs and updates!

Please visit Emersonbearing.com for our latest blogs and updates!